As caretakers of the lands under our temporary stewardship and recognising the unavoidable impact of the mining industry on the environment we strive to take every possible action to ensure the safety of the environment and local communities, as well as the preservation of natural wealth for future generations. This commitment is realised through diligent monitoring, optimal resource utilisation and continuous innovation.

We ensure that all environmental concerns are taken into account and properly addressed during design, construction, operation and closure stages of the mines and processing facilities. We are engaged in multifaceted measures to both mitigate environmental risks and, where possible, to improve ecological conditions around our sites.

At Solidcore, we believe that thoughtful and responsible use of natural resources goes beyond merely meeting the requirements for mandatory environmental protection. Which is why we put significant effort into voluntary projects aimed at supporting and enhancing natural resources in the regions where we operate. Aligning with our commitment to create a positive impact on environment, we are taking our steps towards implementing a Net Positive Impact strategy by launching green projects in regions we operate.

Solidcore has extensive experience in utilising sustainable financial instruments such as green loans and ESG-linked loans, which aligns the company’s strategy and strong ESG performance with responsible capital.

Who is responsible

Our Environmental Policy is designed to overcome environment-related risks from the beginning of a project until long after its completion.

The policy is inseparable from the principles and approaches described in the Group’s other policies covering aspects related to environmental management such as safety, tailings and water storage facilities, carbon emissions, acid rock drainage, mine closure and other. These documents are available at Corporate documents.

The Environmental Management System (EMS) is the cornerstone of our approach and we are proud that all our production sites are certified to global standard ISO 14001. Environmental targets are set within our EMS, both company-wide and at each operational site, with the progress reported in our Integrated Reports.

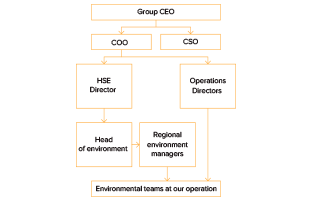

Delivering on our sustainability objectives requires leadership from the very top of the organisation. Our approach is overseen by Board-level committees, with the Group CEO having ultimate accountability.

We have reflected the importance of environmental protection in the Group’s Executive Remuneration policy and reinforced the link between sustainability performance measures and executive remuneration. Each year the Safety and Sustainability Committee considers appropriate climate control performance indicators to be included in the Sustainability/ESG KPI scorecard for the relevant management in line with the Group’s long-term targets.

The products derived from mining are essential to the development and well-being of humanity. However, recognising that mining activities can result in adverse consequences for the climate and simultaneously may suffer from extreme climate events, the Group regards the mitigation of such consequences and adaptation to avoid catastrophic outcomes as essential in the fight against climate change.

For more information on our Climate Strategy and Action Plan, please see the Climate Change And Green Transition section on our website and our recent Integrated Report.

Water plays a crucial role in our processing operations. That’s why monitoring water quantity and quality is one of the key areas of our Environmental Management System (EMS), and our operational facilities are engineered and continuously improved to minimise the extraction of fresh water and guarantee the safe discharge of water.

Recognising water as a shared resource, our approach is inherently community-centric. We acknowledge access to safe and clean water as a fundamental human-rights concern. In every operational region, we conduct assessments of potential water risks, incorporating feedback mechanisms that empower individuals to voice concerns without fear of reprisal, ensuring a thorough investigation of each raised issue.

We also collaborate with local government and community organisations to contribute to long-term water security. This involves funding infrastructure projects and providing assistance in implementing initiatives significant to local communities.

The majority of the water we use is consumed by our plants during ore processing, with most of it circulating in a closed water cycle. We minimise fresh water withdrawal by recycling water and capturing waste water and rainwater that has naturally seeped into our quarries and drainage systems. Some operations consume additional water purchased from local utility companies. As a last resort, we utilise local or state authority permits to extract limited quantities from rivers, dams and groundwater aquifers. However, we never withdraw water from surface sources in environmentally sensitive areas or where eco and bio-services are of great importance to local or indigenous communities.

Water usage is monitored via meters or, when not possible, estimation based on operating time of pumps. We ensure discharge water quality through regular laboratory tests at multiple monitoring points.

Environmental teams at operational sites, as part of our EMS and Climate Management System, are responsible for identifying and assessing water risks. For EMS risks, a one-year time horizon is adopted, relying on historical data related to incidents like pollution or water scarcity, as well as plant technology data. Medium- and long-term risks, such as flooding or changes in precipitation, are evaluated within our Climate Management System, aligning with IPCC climate change projections and the World Resources Institute (WRI) Aqueduct tool, which assesses water-related risks at the catchment level, identifying potential locations facing water scarcity (further details are available in our Integrated Reports and in our CDP Water disclosure).

Waste is an inherent by-product of the entire mining industry which generates significant quantities of mineral waste such as overburden rock and tailings, as well as relatively small quantities of non-mineral and hazardous substance waste. Therefore, waste management has become a fundamental part of our environmental program. While applying rigorous management systems to prevent environmental contamination from waste disposal, our focus is primarily on reusing it when possible, and disposing of remaining products in a way that will not pose a risk to the ecosystem.

Our aim is to increase the share of overburden waste reused and recycled.

As of 2024, Solidcore operates two TSFs in Kazakhstan — at Kyzyl and Varvara. To minimise their environmental impact, we use protective lining, drainage systems, wastewater treatment plants and water collectors. Each TSF undergoes rigorous daily monitoring and inspection, including checks on pipelines, pump stations, water levels and dams. Management reviews their current state monthly, while government agencies regularly assess compliance with safety regulations. Our studies affirm that any emergency failure at our dams would have no impact on settlements, buildings, structures or facilities where communities or employees may be present.

Our TSFs serve as a source of recycled water for processing and upon reaching capacity limits, they undergo dehumidification and reclamation in accordance with our Mine Closure Policy .

We are dedicated to ensuring that all our operations related to TSFs comply with the Global Industry Standard on Tailings Management (GISTM), and highly value the initiatives of the Global Tailings Management Institute in enhancing environmental sustainability and advocating for best practice within the mining industry. In accordance with the GISTM, we have implemented a Tailings and Hydraulic Facilities Management Policy and appropriate internal standards across all our facilities with TSFs, incorporating the fundamental principles outlined by GISTM. Additionally, we conduct annual reporting with detailed information on the status of our TSFs, which is available in our Integrated Report 2023.

In 2023, more than 95% of Solidcore’s total waste generation, by weight, was comprised of overburden. Typically classified as non-hazardous, overburden is either reused or disposed at rock dumps of at our own sites.

To reduce mineral waste disposal, we employ internal dumping, use it for the construction and maintenance of roads and dams at operating sites, and plan backfilling overburden in developed chambers when designing underground mines. Solidcore’s waste management programme envisions a systematic acceleration in the implementation of this practice. For example, by 2027, over 30% of overburden at Varvara will be deposited in pit internal dumps (approximately 1% in 2023). Similarly, at the Kyzyl site, between 2024 and 2027,

Non-mineral waste comprises less than 1% of Solidcore’s total waste generation, but we take extensive measures to recycle non-mineral waste, including paper, plastic and metal, either at our own sites or through accredited organisations. All our production sites are equipped with recycling bins for separate waste collection. In 2023, about 80% of our non-mineral waste was either recycled or reused.

To minimise plastic waste, we now prioritise the reuse of large bags for storing ore concentrate whenever possible. Non-recyclable solid and industrial wastes are neutralized and stored at our designated waste polygons or landfilled by external companies. Environmental monitoring is conducted at all our special waste polygons to assess the quality of air, surface and ground waters, and soils.

Our mining operations generate waste rock as well as hazardous and non-hazardous waste materials. Potentially hazardous substances, such as cyanide, are used in the metals extraction process, while hazardous waste, such as waste fuels and lubricants and fuel filters are byproducts of our operations. At the same time, our waste and emissions do not contain elevated levels of mercury or arsenic.

The management of cyanide, utilised as a leaching agent in the gold recovery process from ore, is subject to stringent controls at every stage to safeguard our personnel and prevent any release into the ecosystem. Our Cyanide Management System ensures a uniform approach to cyanide handling, covering aspects such as procurement, transportation, storage, processing, decommissioning, employee safety, emergency response, training and stakeholder engagement. This system is currently implemented across all operational sites where cyanide is utilised.

Our methodology entails identifying all associated hazards, maintaining strict control over cyanide levels in tailings, collaborating with third-party cyanide producers and transporters, and conducting comprehensive monitoring of air, soil, surface and groundwater. We design, construct and monitor tailings dams to prevent cyanide effluent and share all relevant data with public authorities and other stakeholders upon request.

Solidcore is a signatory of the Cyanide Management Code. Our sole cyanide-related site, Varvara, is fully certified both as a gold mining company and separately as a cyanide transporter. In 2022, the site underwent an independent audit for compliance with the Cyanide Code and, in 2023, we updated the internal Standard for Cyanide Management and provided training to the responsible personnel at the site.

Detailed information on the compliance status at our sites with the Cyanide Code is available on the ICMI website.

In accordance with the national legislation of Kazakhstan, hazardous waste generated during our activities includes tailings, as well as a relatively small amount of waste oils, oil filters, batteries and other non-mineral hazardous waste.

To eliminate any environmental risks related with tailings, each TSF undergoes rigorous daily monitoring and inspection, including checks on pipelines, pump stations, water levels and dams. Management reviews their current state monthly, while government agencies regularly assess compliance with safety regulations. Our TSFs serve as a source of recycled water for processing and upon reaching capacity limits, they undergo dehumidification and reclamation in accordance with our Mine Closure Policy . We conduct annual reporting with detailed information on the status of our TSFs, which is available in our Integrated Report 2023.

The entire volume of hazardous non-mineral waste is neutralised or recycled at our sites or by specialised organizations. We strictly monitor the correct handling of hazardous non-mineral waste, preventing its placement in landfills and making unconditional priority of recycling over neutralization (where possible).

As is unavoidable with all mining projects, our core activities generate air emissions, including carbon dioxide, nitrogen, sulphur oxides, and inorganic dust, which is the primary type of emissions pollutant produced throughout our activities.

Our EMS includes robust systems that continually monitor these gases and particulates, as well as enabling us to continually refine our processes to ensure high air quality standards. For instance, around our mining sites, we continually improve irrigation, dust separation and shield technologies to minimise local impact.

From the initiation of a mining project, we assess the impacts on biodiversity through an Environmental Impact Assessment, involving collaboration with environmental organisations and local communities. Subsequently, ongoing site-specific biodiversity monitoring is conducted, encompassing studies of plant and animal life around our mining sites in partnership with local biodiversity experts. Alongside scientific monitoring, we have established a framework for prompt reporting of biodiversity-related incidents, with a specific focus on those resulting in harm to or fatalities of wildlife.

Following the Science Based Targets for Nature Initial Guidance for Business, we have recognised land use change resulting from mining and related infrastructure as the primary pressure on biodiversity, water bodies and natural carbon sinks. The IUCN Guidelines for Planning and Monitoring Corporate Biodiversity Performance have assisted us in identifying priorities concerning protected areas and species.

We determine our biodiversity impacts through our regular site-specific biodiversity management surveys. They imply regular studies and monitoring of our mining sites and adjacent areas, which we conduct in collaboration with local scientific institutions.

In addition to scientific monitoring, we have developed a framework to promptly report on any cases related to biodiversity, focusing on those that lead to any wildlife harm or mortalities. This complements annual biodiversity reports prepared at every site within the Environmental Management System. The report includes the list of rare and hunted species found at our mining site or adjacent territories during the year.

Altogether, this helps us analyse our environmental impact on fauna and flora and plan further activities, prioritizing preventive measures over compensatory ones:

- avoiding building on migratory routes or close to environmentally-protected or indigenous peoples’ territories;

- minimising impact to existing sites by adopting safe and clean technologies, such as dry stacking of tailings;

- installing bird deterrents at waste polygons and tailing storage facilities;

- surrounding our open pits with waste rock walls to prevent animals from falling in;

- installing road signs that warn about wild animals;

- planning proper mine closure activities and land rehabilitation;

- planting perennial herbs and trees in adjacent territories;

- educating and engaging employees and communities.

To increase efficiency of our Environmental Management Program on biodiversity and to identify threats to biodiversity loss, at all stages of mine life, we cooperate, exchange knowledge and experience with local, national and international scientific and expert centers, local communities, state authorities in the regions where we operate. We commit to transparency and open communication while complying with applicable legal requirements.

Responsibility on biodiversity conservation lays primarily on environmental teams, operations management, relevant managers, and on the Safety and Sustainability Committee of the Board of Directors. Additionally, our communication teams are training and involving our employees and local communities in environmental and biodiversity awareness programs. See more here.

Under the legal requirements of countries where we operate, we are not allowed to mine or produce metals in areas with the highest biodiversity value. Our operations are regularly monitored by state authorities responsible among others for biodiversity conservation and if they detect any negative impact on biodiversity, we will develop measures together with authorities to mitigate these impacts and achieve no net loss.

In addition, as part of our commitment to actively fostering a favourable environment for all stakeholders in our operating regions and taking initial steps towards implementing a Net Positive Impact approach, we are undertaking a voluntary pilot project to plant a new forest not far from Varvara site in Kazakhstan. For more information on our afforestation initiative, please see the Climate Change And Green Transition section on our website and our recent Integrated Report.

As of 2024, Solidcore has no operating assets and development or exploration projects located within the permafrost zone. In March 2024, as a part of disposal of Russian business, Solidcore sold all the permafrost-located assets. Thus, all climate risks associated with permafrost are currently not relevant for Solidcore.

Mining and the effects thereof have an impact on the environment around our mines. This is caused by quarrying and infrastructure such as storage, waste, tailings and roads. It is our priority to work with state bodies, local communities and our employees to mitigate the long-lasting effects of our operations after the closure of our mines.

Our long-term remediation obligations include fulfilling decommissioning and restoration liabilities and covering suspension or abandonment costs in compliance with national regulations and legislation. The Company covers these costs. We carry out geological, surveying and repair works to ensure that once a mine is suspended or abandoned, underground operations, drilling sites and buildings are not hazardous or dangerous. Additionally, we carry out necessary environmental rehabilitation.

Solidcore aims to minimise negative impacts on the environment and stakeholders by ensuring the safety and stability of sites and facilities after closure and ensures that they are left in a condition which is compatible with subsequent land uses for local communities in regions of our operation without threat to human health. In doing this, Solidcore adheres to a list of key principles in the course of mine closure:

- to disseminate effective and comprehensive closure planning practices for the Company;

- to encourage employees, management and partners to demonstrate leadership;

- to ensure that closure planning reflects legal and regulatory requirements;

- to apply state-of-the-art technologies for the mine closure;

- to ensure that adequate resources are available for the closure process;

- during the operation stage, to rehabilitate as much land as possible prior to closure and to decrease the level of landscape alteration (use pit for waste rock and tailings storage, backfilling and use of waste rock for construction);

- to consider the concerns of stakeholders (local communities, governments, employees and landowners) in closure plans;

- to conduct post-closure monitoring until the responsibilities are transferred to a third party.

Solidcore takes responsibility for compliance with the requirements of applicable laws and strives to meet stakeholders’ expectations when closing a mine. For these reasons, our priorities of effective mine closure include:

- to provide timely and effective closure planning and implementation of related measures;

- to reduce financial, social and environmental risks when the operation closes and optimize social, economic and cultural opportunities for the host community;

- to ensure the safety and stability of structures and facilities during and after the closure and for further and subsequent use;

- to ensure that adequate financial resources are available to meet the full cost of closure;

- to ensure that business is conducted in a socially responsible way and that obligations towards the dismissed personnel are met.

We aspire to a comprehensive approach to mine closure in cooperation with the relevant bodies, stakeholders, our employees and contractors, and local communities in order to effectively mitigate long-lasting environmental effects, while taking continued responsibility for the mine, the environment and our employees after closure.

In line with our commitment to Occupational Health and Safety, we want to ensure preparedness for all types of emergencies that may pose threat to the safety of people and the environment. We conduct emergency drills and test our response plans across all our hazardous facilities at least annually and at least monthly at the facilities with higher emergency risks.

All Solidcore’s emergency response plans are fully compliant with the applicable regulations. With the support of local authorities, Solidcore has created an action plan to practice emergency prevention at each of our hazardous facilities. We provide training for our in-house first responders and engage contractors for accident prevention and potential rescue work. Solidcore’s emergency preparedness effort is underpinned by:

- Continuous improvement of the Occupational Health and Safety Management System implemented across all of our operations;

- Active licenses and permits required for certain types of safety-related measures;

- Safety inspections of all buildings, constructions and facilities associated with hazardous activities;

- Valid insurance policy for liability coverage in case of emergencies.

To identify emergency risks and their potential harm to the environment, we:

- Put together a comprehensive list of possible emergencies;

- Ensure that our hazardous facilities are listed in the official register of the governmental body;

- Develop emergency response procedures;

- Procure insurance for the hazardous facilities.

We use the following data for our emergency preparedness planning:

- Information on global environmental disasters and their causes;

- Audit and inspection records, environmental impact reports, safety assurance documentation and on-site checks records;

- Statutory audit reports;

- Constantly updated environmental monitoring data.

In 2016, the European Bank for Reconstruction and Development (EBRD) and Wardell-Armstrong (WAI) completed a detailed review of the social and environmental issues linked to our Kyzyl gold project in north-eastern Kazakhstan.

Based on this review, a formal Environmental and Social Impact Assessment (ESIA) has been produced by WAI for meeting environmental and social requirements of the EBRD, which is considering the opportunity to finance the project.

The ESIA is a comprehensive analysis of any risks and opportunities linked to all key areas of the Kyzyl project, including its environmental, socio-economic and cultural effects.

Solidcore has also agreed with the EBRD on the Environmental and Social Action Plan (ESAP), which includes a series of actions that Solidcore will implement in order to avoid, reduce, control, or otherwise mitigate potential environmental, occupational health and safety and social impacts during Kyzyl construction and operation.

ESIA summary

- Executive Summary: Russian | English | Kazakh

- Supplementary Environmental and Social Report (SESR): Russian | English | Kazakh

- Environmental and Social Impact Assessment (ESIA): Russian | English | Kazakh

- Management Plans: Russian | English | Kazakh

- Stakeholder Engagement Plan: Russian | English | Kazakh

- Non-Technical Summary: Russian | English | Kazakh

- Environmental and Social Action Plan (ESAP): Russian | English | Kazakh

ESIA Contacts

Bakyrchik Mining Venture LLP

Address: Building 30 G, Quarter A, Auezov village, Zharma area, East Kazakhstan

region, 070605, Republic of Kazakhstan

Contact Name: Chief Ecologist Denis Nekrylov

Telephone: +7 (7232) 492 600 (ext.125)

Fax: +7 (7232) 492 601

Contact

via e-mail

Office of the mayor of Auezov village

Address: Mira 90 B, Auezov village, Zharma Area, East Kazakhstan Region, 070605,

Republic of Kazakhstan

Contact Name: Chief specialist at the Office of the mayor of Auezov

village — Ulzhan Duisen

Telephone: +7 (72347) 55 200